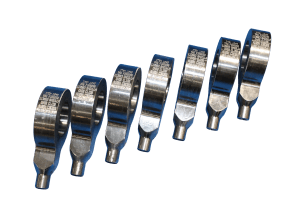

Bleed Rings & Bleed Inserts

Industrial bleed rings and bleed inserts provide essential pipeline access for fluid sampling, pressure monitoring, chemical injection, and system drainage. Available in 15mm-1500mm sizes with multiple port configurations (socket weld, threaded, flanged), these ASME-compliant components are manufactured in carbon steel, stainless steel, and specialty alloys for petrochemical, mining, and process engineering applications. Also known as test inserts, drip rings, and flushing rings.

Size Range and Specifications

Size Range |

15mm to 1500mm (1/2"-60") |

|---|---|

Pressure Ratings |

150lb-2500lb (ASME B16.5) |

Sealing Types |

Flat Face, Raised Face, Ring Joint |

Surface Finish |

Spiral Finish 3.2-6.3 µm |

Port Options |

Socket Weld, Threaded, Flanged |

Delivery |

Standard: Same-day Delivery, many sizes ex stockCustom: 5-10 days |

Also Known As |

Bleed Rings with holes, Test Inserts, Drip Rings, Flushing Rings |

Custom Manufacturing - Bleed Rings

Our ISO 9001 certified facility handles specialized requirements including:

- Custom materials and construction methods

- Fabricated designs with approved weld procedures

- Complete material traceability with ITP/MDR documentation

- Project-specific packaging and specifications

- 10-20 days for custom items, many sizes in stock.

As an ISO 9001 certified manufacturer, we accommodate specialized engineering requirements through custom material selection and construction methods. Our comprehensive quality system includes full material traceability, detailed testing documentation, and approved weld procedures. We provide complete documentation packages including ITPs, MDRs, and weld certification. All products can be packaged to meet your specific engineering or project requirements, delivered within rapid timeframes.

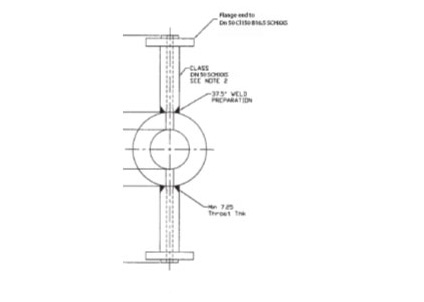

What Are Bleed Rings?

Bleed Rings are specialized pipeline components that create controlled access to fluid flow. Key features and functions:

- Acts as a spacer between pipe flanges

- Provides access points for fluid control

- Standard thickness of 38mm

- Compatible with ASME B16.5 standards

Standards: Manufactured to ASME B16.48, suitable for use with ASME B16.5 flanges. We also comply with a range of international standards and custom specifications.

Applications:

- Fluid sampling and analysis

- Pressure venting and relief

- System drainage and maintenance

- Chemical injection and flushing

- Instrumentation access

- Process monitoring

Material Selection and Configurations - Bleed Rings

Bleed Ring Standard Materials:

- Carbon Steel: A516 GR70, AS1548-PT460 (NR), A105, LF2, AS1548 460NR, A350 LF2, A350 LF3

- Stainless Steel: 304/304L, 316/316L, A240 P316L, UNS31803 (Duplex)

- Specialty Materials: Super Duplex 2205, Incoloy 625, Custom materials available

Each configuration can be customized with various port combinations to suit specific applications.

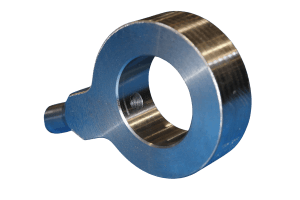

Bleed Ring Port Options

Machined directly into the ring:

- Socket weld ports

- Tapped (threaded) ports

- Flanged connections

Available Configurations

Four standard designs available:

- Basic ring with 1-2 ports

- Bolt-hole ring with 1-2 ports

- Extended access (one-piece with extension)

- Flanged design

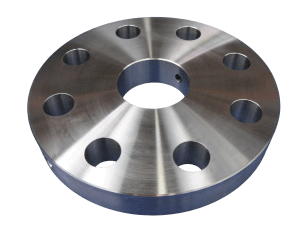

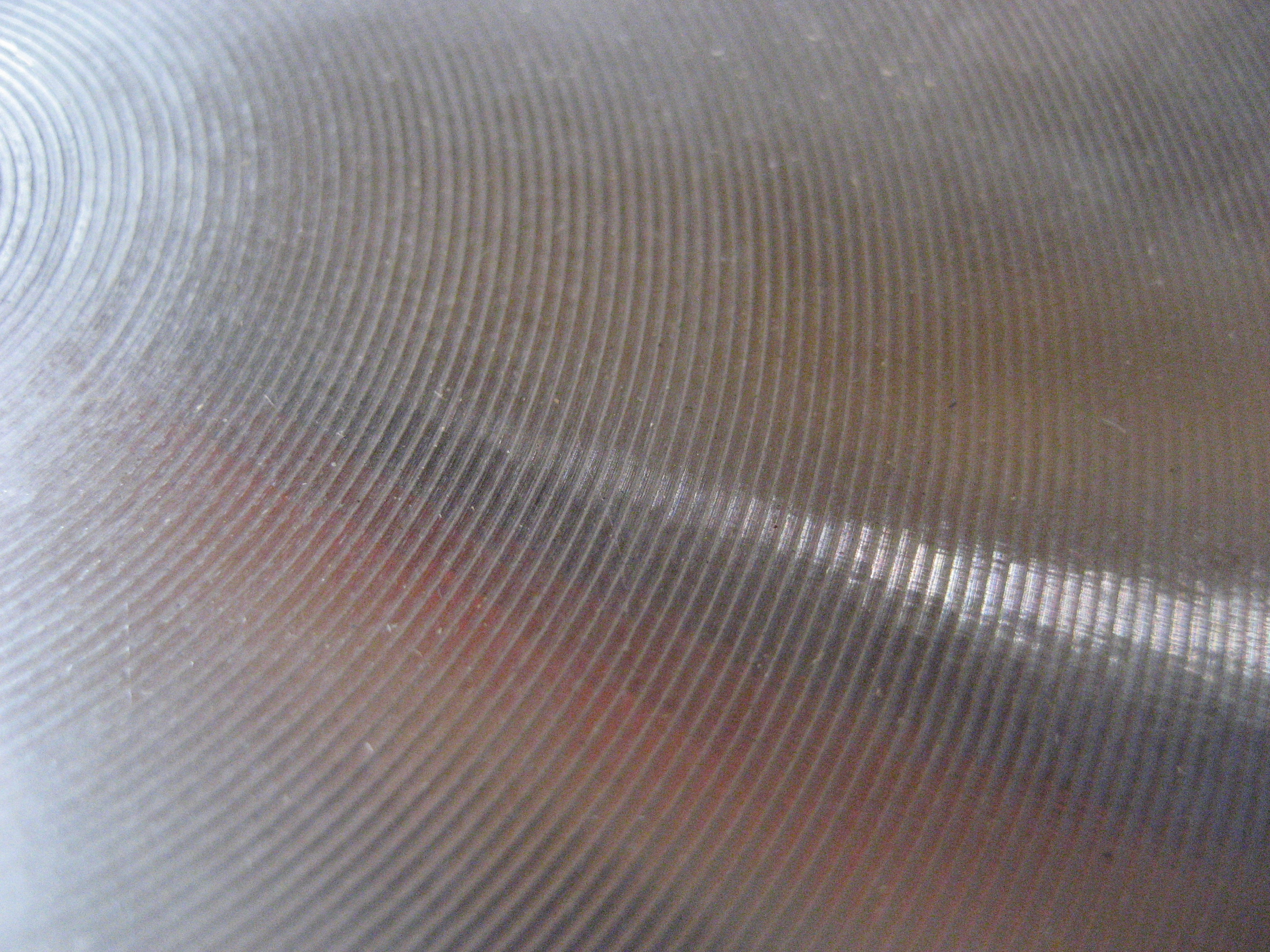

Sealing Face Finishes - Bleed Rings

Bleed Rings: Raised Face, Spiral Finishes

Spiral Sealing Facing

All sealing surfaces feature a spiral finish with Ra 3.2µm-6.3µm surface roughness for optimal performance.

Customized Ring Joint Sealing Facing

For high pressure applications, ring joint seals are often used.

Stamping - Bleed Rings

Each product includes:

- Size and rating stamps

- Material grade

- Heat number

- Production traceability

- Optional client identification

- ISO 9001 certification

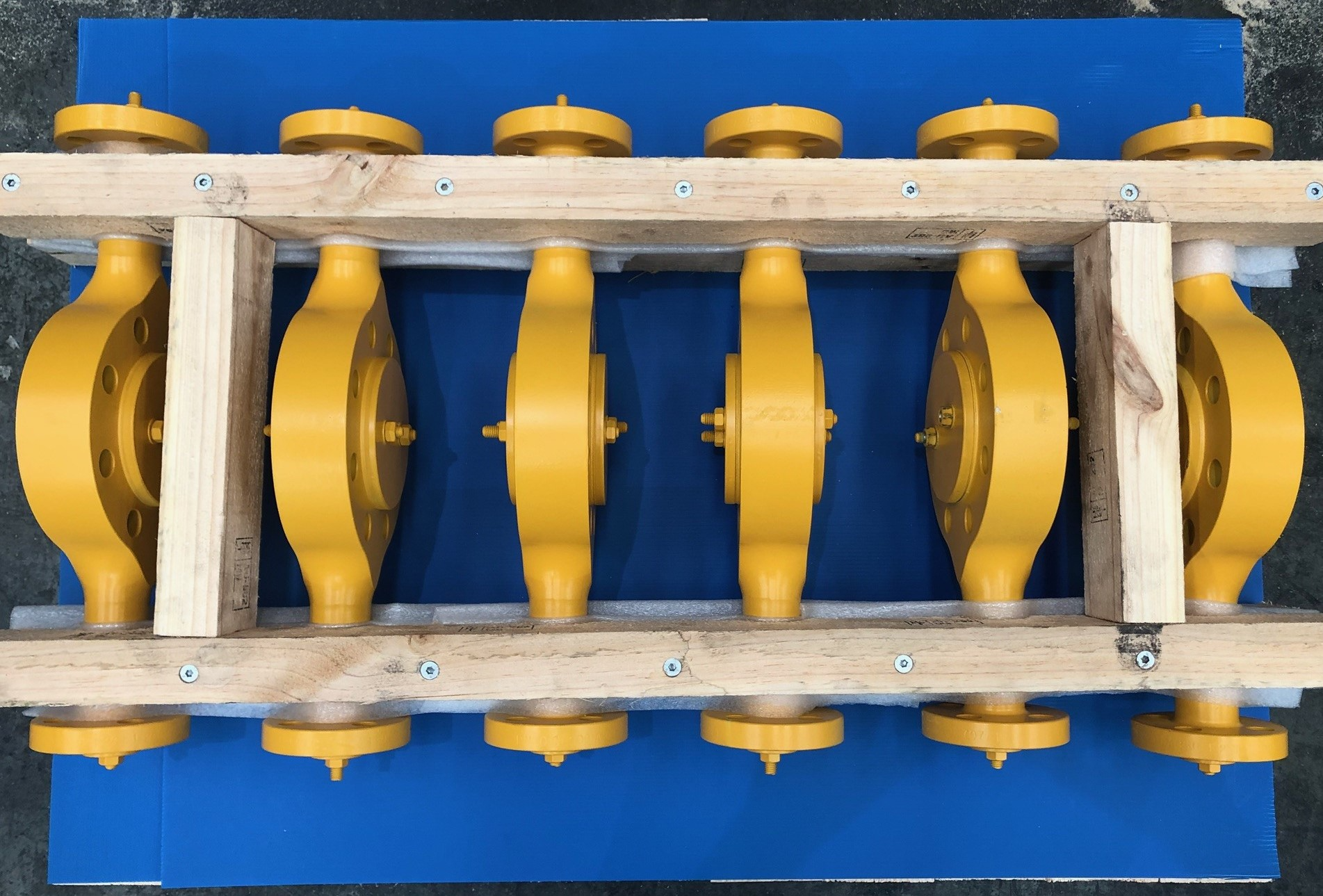

Surface Protection - Bleed Rings

Our products feature:

- Dual sealing face protection

- Short-term (2 weeks) to long-term (2 years) options

- Special finishes available:

- Even more robust corrosion protection can be supplied upon request.

- Galvanizing

- PTFE coatings and linings

- Epoxy finishes

Custom packaging solutions are also available to meet your specific requirements.

Key Features and Applications

Design Options

- Four standard configurations

- Multiple port combinations

- Custom dimensions available

- 38mm standard thickness

- ASME B16.5 compatibility

Quality Standards

- ISO 9001 certified manufacturing

- Full material traceability

- Comprehensive documentation

- Surface finish certification

- Pressure testing available

Industrial Applications

- Fluid sampling systems

- Pressure relief points

- Chemical injection ports

- System drainage access

- Process monitoring points

Technical Support

- Custom engineering solutions

- Material selection guidance

- Technical documentation

- Rapid manufacturing service

- Installation consultation

Need Standard or Custom Bleed Rings and Inserts?

Contact our knowledgeable team today to discuss your bleed ring requirements.

Get A Quote