Orifice Flanges and Orifice Plates

Caman Engineering manufactures precision orifice flanges and orifice plates that meet ASME B16.36 standards. Our flow measurement systems provide reliable solutions for industrial flow monitoring and process control.

Size Range and Specifications

Size Range |

15mm-1500mm (1/2"-60") |

|---|---|

Ratings |

150lb-2500lb as per ASME B16.45 |

Sealing Type |

Flat Face, Raised Face, Ring Type Joint |

Surface Finish |

Spiral finish Ra 3.2µm to 6.3µm |

Also Known As |

Metering Flanges, Restriction Plates |

Custom Manufacturing - Orifice Plates and Orifice Flanges

Our ISO 9001 certified facility handles specialized requirements including:

- Customizable port configurations: - Screwed ports - Socket welded ports - Flanged extension ports

- Special material selection and construction methods

- Complete material traceability with ITP/MDR documentation

- Project-specific packaging and specifications

- Rapid delivery for custom solutions

As an ISO 9001 certified manufacturer, we specialize in custom orifice flanges designed to meet specific engineering requirements. Our expertise in port customization allows for various configurations and connection types. Our comprehensive quality system includes full material traceability, detailed testing documentation, and certification packages. All products can be manufactured and packaged according to your project specifications, delivered within rapid timeframes.

What Are Orifice Flanges?

Orifice Flanges and Plates form a specialized measurement system for fluid flow in pipelines. The complete system consists of:

- Two Ported Flanges with pressure taps

- Precision-engineered Orifice Plate

- Sealing plugs

- Jacking bolt

- Optional assembly bolts

The system measures flow rates by creating and monitoring pressure differentials between the upstream and downstream sides of a precisely sized aperture, using fluid dynamics principles.

Applications:

Our orifice measurement systems are crucial for:

- Flow monitoring

- Process control

- Energy management

- Pipeline measurement

- Resource consumption tracking

What Are Orifice Plates?

The Orifice plate is the central component of the flow measurement system, positioned between two Orifice flanges. Its precisely engineered aperture, combined with process parameters, enables accurate flow rate calculations.

- Maintains the technical relationship between components

- Clarifies the plate's purpose

- Emphasizes the measurement aspect

- Uses more precise technical language while remaining accessible

Material Options - Orifice Plates and Orifice Flanges

| Orifice Flanges | Orifice Plates | |

|---|---|---|

| Stainless Steels |

|

|

| Carbon Steels |

|

|

| Special Materials |

|

|

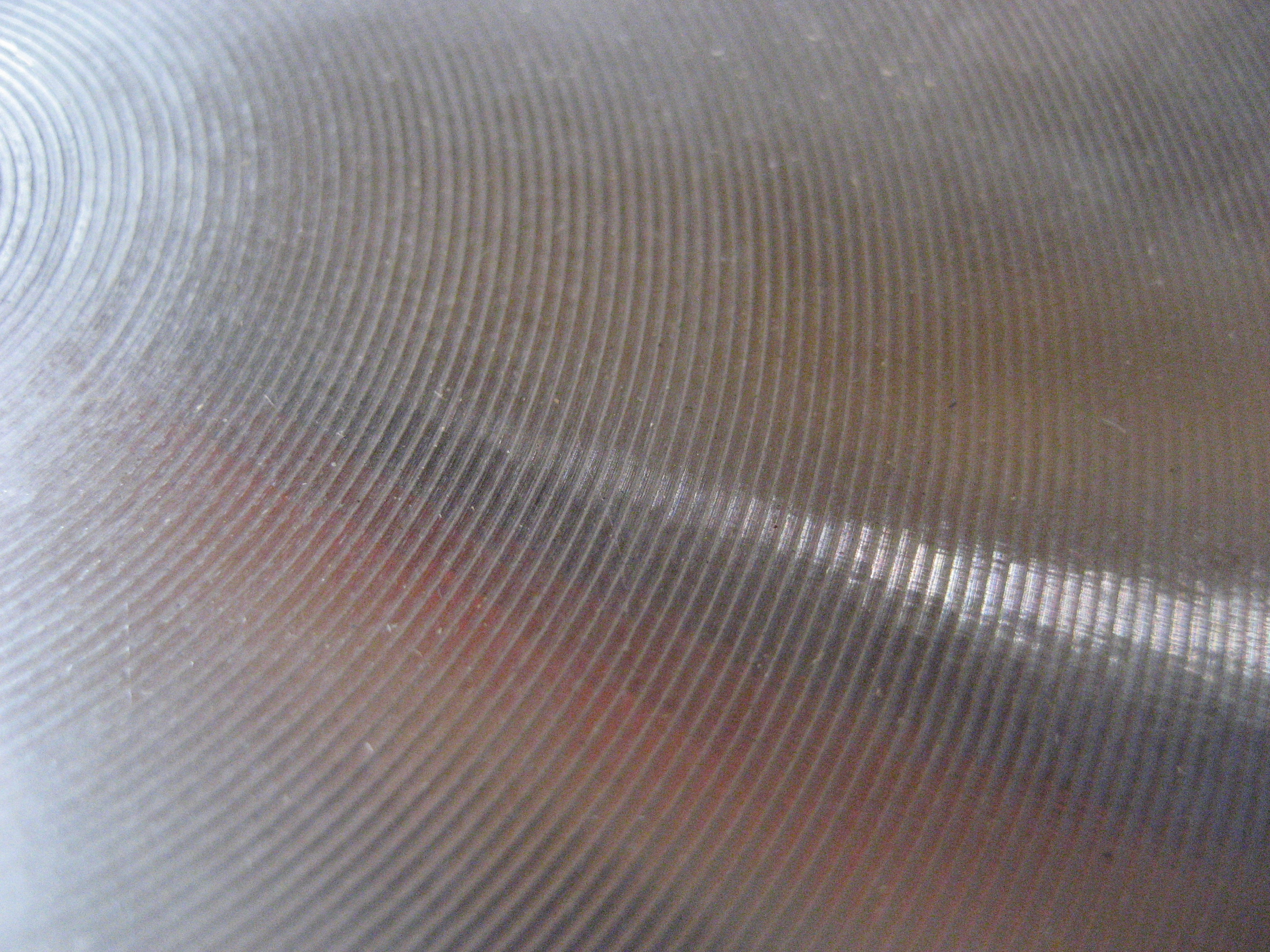

Sealing Face Finishes - Orifice Flanges and Orifice Plates

Spiral Sealing Face Finishes for Orifice Flange and Orifice Plate

Spiral Sealing Facing

All sealing surfaces feature a spiral finish with Ra 3.2µm-6.3µm surface roughness for optimal performance.

ASME B16.5 compliant finishes

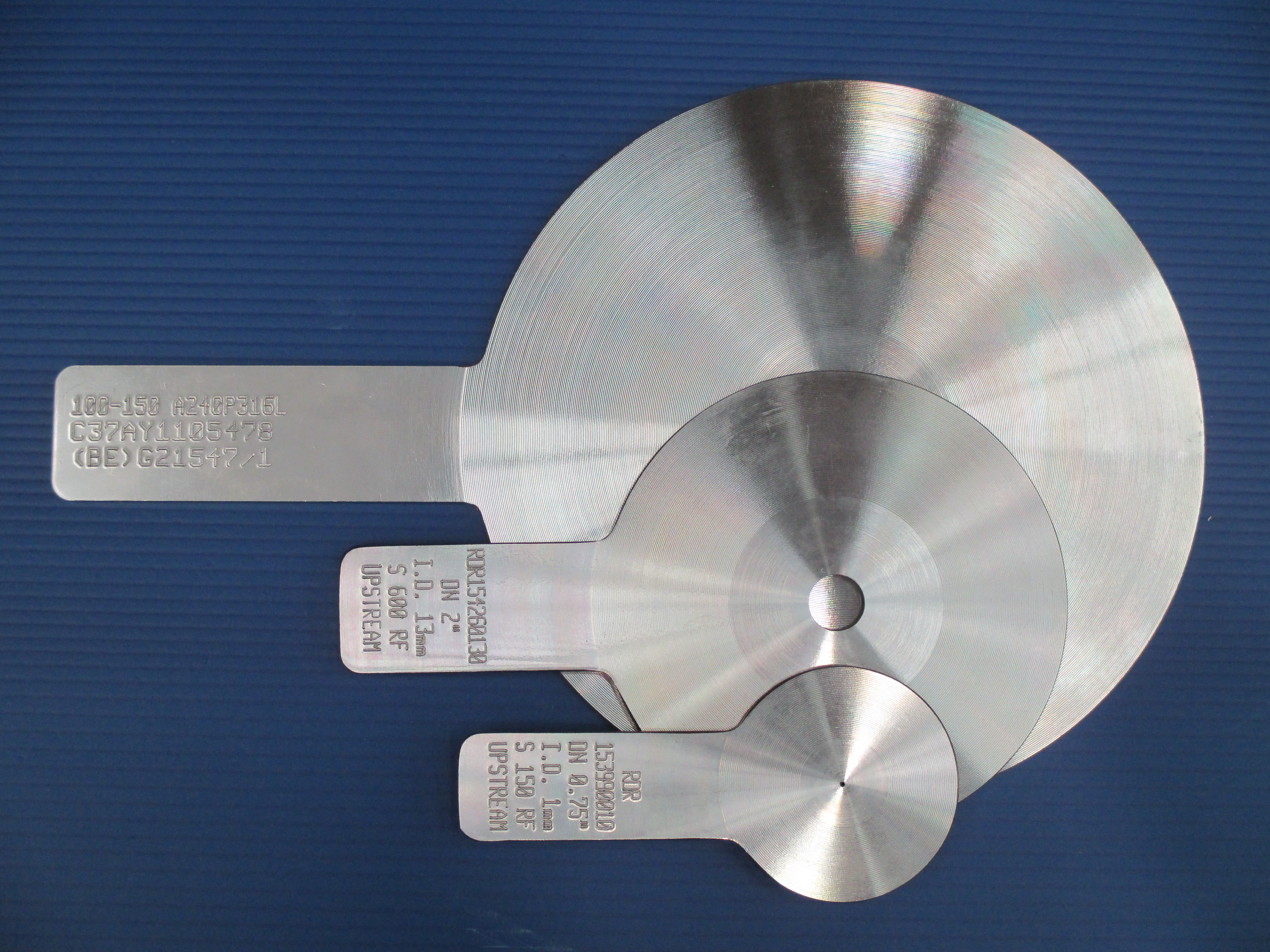

Stamping - Orifice Plates and Orifice Flanges

Each product includes comprehensive stamping:

- Size and pressure rating

- Material grade

- Heat number

- Manufacturer's stamp

- Traceability code

Custom markings are available upon request.

Surface Protection - Orifice Plates and Orifice Flanges

Our products feature:

- Dual sealing face protection

- Short-term (2 weeks) to long-term (2 years) options

- Enhanced corrosion protection available

- Even more robust corrosion protection can be supplied upon request:

- Galvanizing

- PTFE coatings and linings

- Epoxy finishes

Custom packaging solutions are also available to meet your specific requirements.

Key Features and Applications

Design Features

- Precision-engineered aperture

- Dual pressure tap ports

- Multiple port configurations

- Customizable connections

- ASME B16.36 compliance

Flow Measurement

- Accurate flow monitoring

- Process control systems

- Energy management

- Resource consumption

- Pipeline measurement

Quality Assurance

- ISO 9001 certification

- Material traceability

- Pressure testing

- Dimensional accuracy

- Surface finish verification

Technical Support

- Custom engineering solutions

- Material selection guidance

- Installation consultation

- Documentation packages

- Rapid manufacturing service

Need Standard or Custom Orifice Flanges and Plates?

Contact our knowledgeable team today to discuss your flow measurement component requirements.

Get A Quote