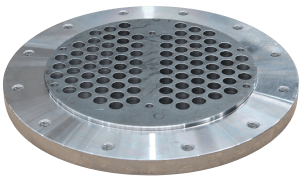

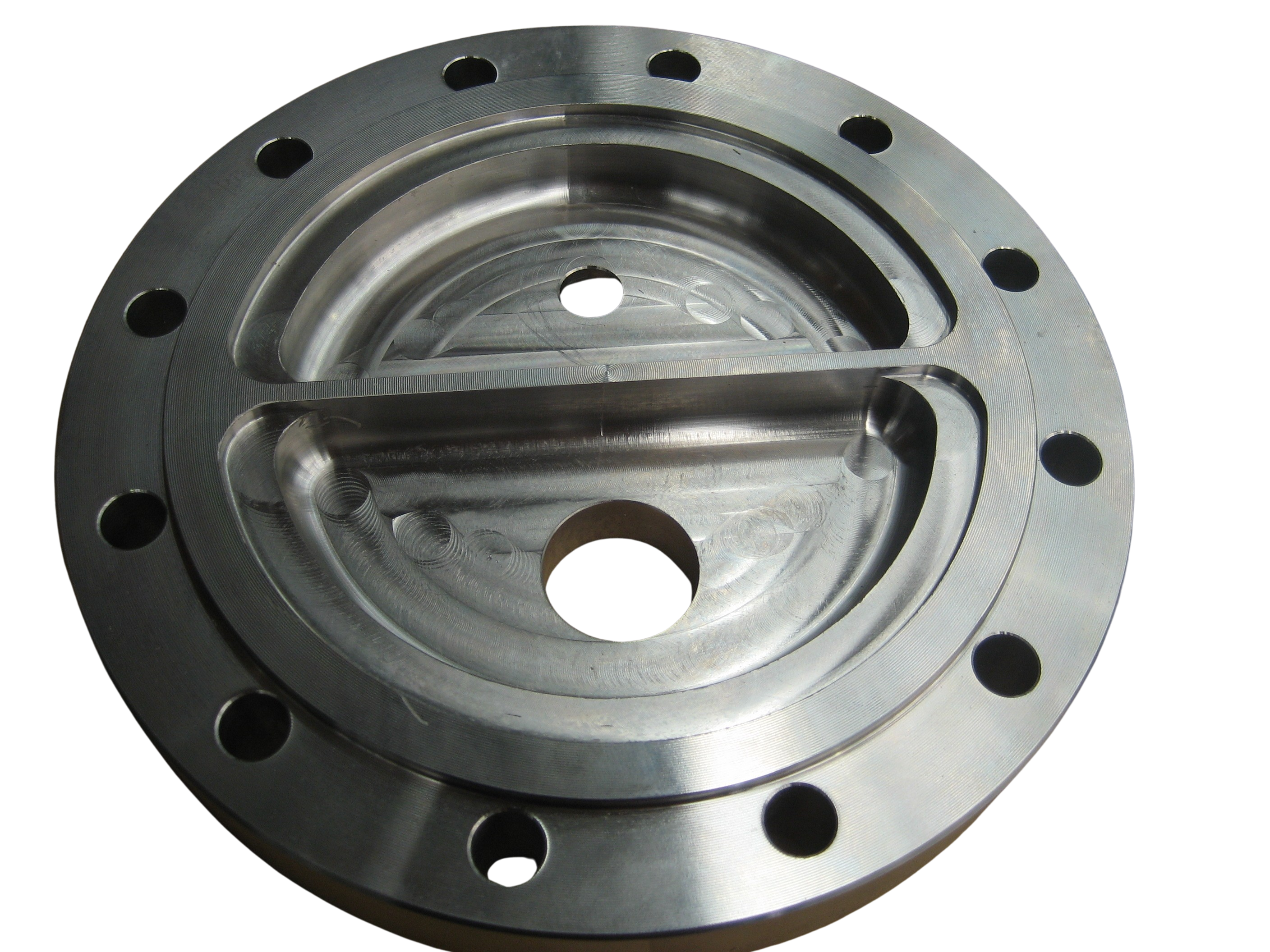

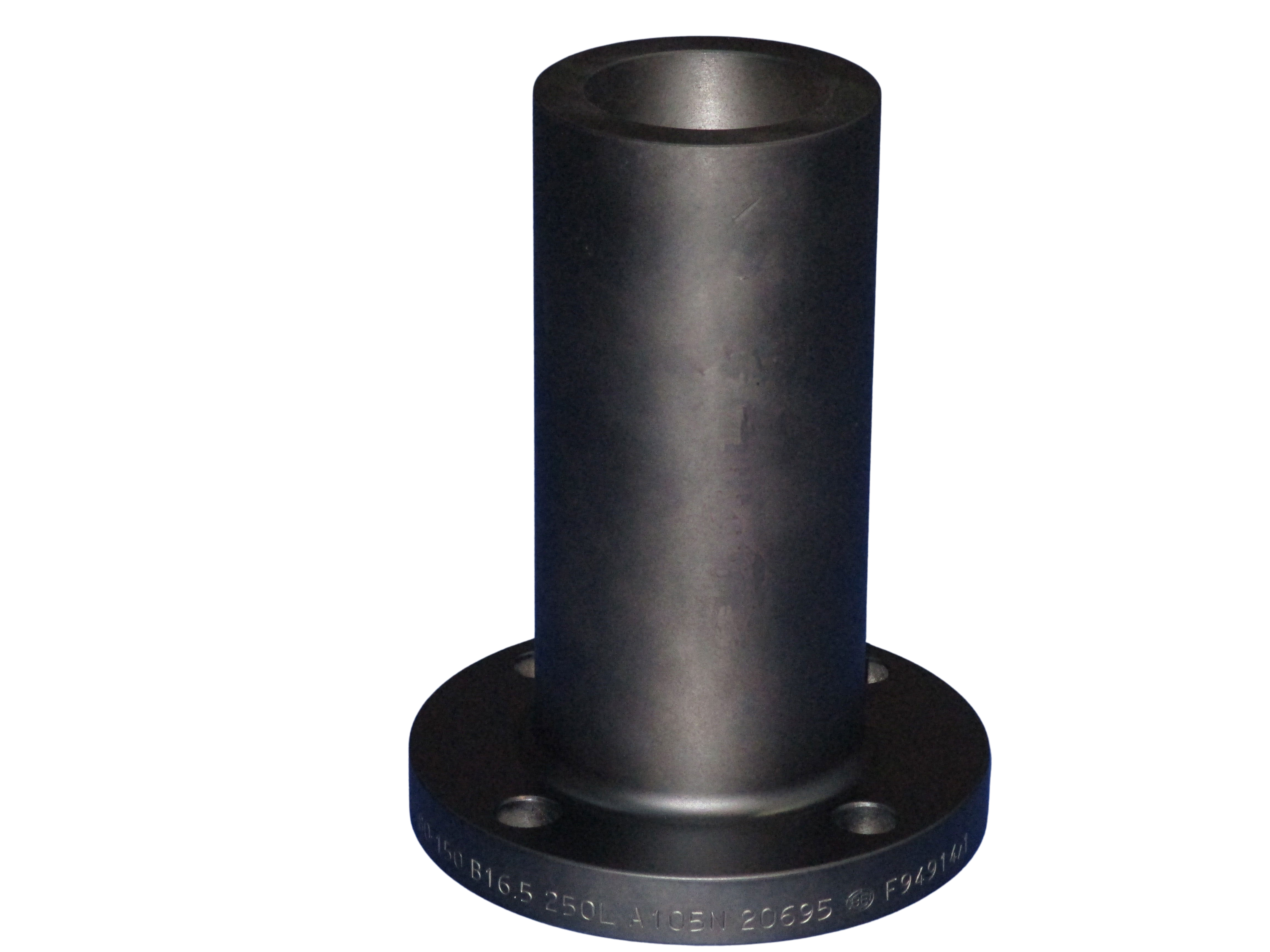

Each tube plate is specifically designed by the client for its pressure vessel and desired performance. We offer customizable sealing faces with spiral surface finish to industry standards and options for 'O'-ring seals in floating tube plates.

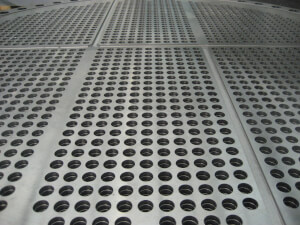

Special features include multiple grooves and slots, unusual hole sizes, different bolting patterns, and a range of special materials.