Spectacle Blinds, Spades, and Spacers | Fig 8 Blinds, Paddle Blinds

Caman Engineering manufactures high-quality spectacle blinds, spades, and spacers for effective pipeline isolation and flow control.

Size Range and Specifications

Size Range |

15mm to 1500mm (1/2" to 60") |

|---|---|

Pressure Ratings |

150lb to 2500lb (ASME B16.48) |

Sealing Options |

Flat Face, Raised Face, Ring Joint |

Surface Finish |

Spiral Finish 3.2-6.3 µm (Ra) |

Delivery |

Standard: Same-day Delivery, many sizes ex stockCustom: 5-10 days |

Also Known As |

Figure 8 Blinds, Spectacle Blanks, Line Blinds |

Custom Manufacturing - Spectacle Blinds, Spades and Spacers

Our ISO 9001 certified facility handles specialized requirements including:

- Maintains focus on customization capability

- Highlights quality certification

- Includes all documentation types

- Preserves emphasis on traceability

- Retains mention of quick delivery

As an ISO 9001 certified manufacturer, we offer customized Spectacle Blinds designed to meet specialized engineering requirements. Our comprehensive quality system includes full material traceability, complete testing documentation, and certification packages (ITPs and MDRs). All products can be manufactured and packaged according to your specific project requirements, with rapid delivery timeframes.

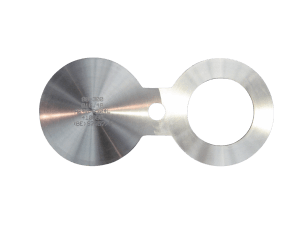

What are Spectacle Blinds?

Spectacle Blind: Raised Face, Spiral Finishes

A dual-purpose isolation device featuring:

- Figure-8 design with solid blind and open spacer sections

- Simple rotation mechanism for flow control

- Visual confirmation of line status

Standards: Manufactured to ASME B16.48, suitable for use with ASME B16.5 flanges. We also comply with a range of international standards and custom specifications.

What are Spades and Spacers?

Spade & Spacer Ring Joint Finishes

Separate components ideal for larger pipelines:

- Spade: Solid plate for line isolation

- Spacer: Open plate for flow continuation

- Visual indication through handle design

Standards: Produced in accordance with ASME B16.48 (similar to API 590), covering sizes up to 600mm nominal bore depending on pressure class. We can manufacture to other standards or company-specific drawings upon request.

Also known as: Line Blinds, Paddle Blinds

Material Selection - Spectacle Blinds, Spades and Spacers

- Carbon Steel: A516 GR70, AS1548-PT460 (NR), A105, LF2

- Stainless Steel: 304/304L, 316/316L, UNS31803

- Special Alloys: Super Duplex 2205, Incoloy 625 (upon request)

Sealing Face Finishes - Spectacle Blinds, Spades and Spacers

Spectacle Blind: Raised Face, Spiral Finishes

Spiral Sealing Facing

All sealing surfaces feature a spiral finish with Ra 3.2µm-6.3µm surface roughness for optimal performance.

Ring Joint Sealing Facing

For high pressure applications, ring joint seals are often used.

Stamping -Spectacle Blinds, Spades and Spacers

Each product includes:

- Size and rating stamps

- Material grade

- Standard specification

- Heat number

- Production traceability code

- Caman Engineering Stamp

- Optional client identification and process traceability

Surface Protection - Spectacle Blinds, Spades and Spacers

Available options:

- Galvanized finishes

- PTFE coatings and linings

- Custom epoxy finishes

- Short-term (2 weeks) to long-term (2 years) protection

Key Features and Applications

Design Features

- ASME B16.48 compliant

- Custom handle designs

- Various material options

- Precision machined surfaces

- Multiple size ranges

Quality Assurance

- ISO 9001:2015 certified

- Material traceability

- Dimensional verification

- Surface finish testing

- Quality documentation

Applications

- Pipeline isolation

- System maintenance

- Safety lockout points

- Process separation

- Emergency shutdown

Technical Support

- Custom engineering

- Material consultation

- Technical documentation

- Installation guidance

- Rapid manufacturing

Need Standard or Custom Spectacle Blinds, Spades and Spacers?

Contact our knowledgeable team today to discuss your component requirements.

Get A Quote